Дизельное топливо в автомобилях может сгорать только при определенных условиях, обеспечивающих высокое давление. Поэтому в машинах с дизельным двигателем используется топливный насос высокого давления (сокращено ТНВД). Что представляет собой этот узел, какой у него принцип работы, какая его роль в целом? Это должен знать каждый автомобилист. Сейчас поговорим о том, что это ТНВД, какую функцию он выполняет.

ТНВД: что это

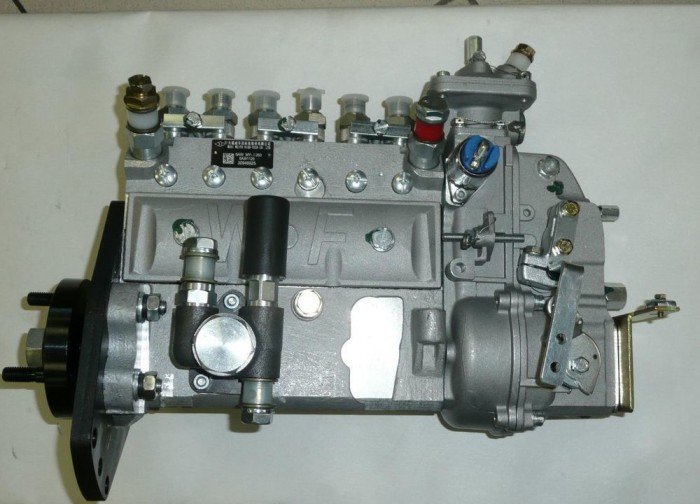

Топливный насос является крайне сложным с конструктивной и технической точки зрения узлом, обеспечивающим подачу дизельного топлива в камеру сгорания двигателя. Система делает это автоматически: под определенным давлением в нужное время. Однако наиболее точной формулировкой функционирования ТНВД называют его возможность создания высокого давления дизеля, при котором он сгорает в полном объеме. Процесс способствует увеличению мощности двигателя.

Принцип работы топливного насоса

Дизельный двигатель сам по себе является сложным механизмом, эффективная работа которого зависит от топливного насоса. Интересует вопрос о том, что такие ТНВД в дизелях? Принцип работы заключается в создании давления более чем 150 Мпа. Стоит отметить, что это высокая планка, которую, чтобы достичь, ТНВД должен соответствовать ряду требований. Одно из них – качественный материал изготовления. Поддаваясь высоким нагрузкам и температурным скачкам, насос прежде должен быть сверхпрочным и надежным. Для этого производители используют особые алюминиевые сплавы АЛ9. Высокие требования предъявляются и к плунжерной паре цилиндра и стержня. Детали должны быть выполнены из высокопрочной стали, выдерживающей высокие нагрузки.

Разновидности ТНВД

Дизельные моторы отличаются друг от друга моделями, даже поколениями. Соответственно, каждый вид двигателя нуждается в подходящем топливом насосе, из-за чего их принято классифицировать по ряду признаков:

- Рядные ТНВД. Особенность механизма – плунжерные пары на каждый цилиндр. Несмотря на расположение в одном ряду, дизель подается по разным каналам к распыляющим форсункам. Запускаясь, вращение мотора передается на кулачковый вал. Под воздействием кулачков элементы каждой плунжерной пары начинают двигаться. Это заставляет плунжеры перемещаться по цилиндру, сжимая под высокой температурой воздух. Когда давление сжатого воздуха превышает определенную отметку, срабатывает впускной клапан. Через его отверстие распиленная солярка попадет в камеру сгорания. Рядные ТНВД нашли свое применение в больших или грузовых автомобилях. Они зарекомендовали себя как выносливые и надежные системы.

- Распределительные ТНВД. Количество дизеля регулируется несколькими плунжерами. Топливо подается через распределительную головку и каналы. Своей популярности такие ТНВД обязаны небольшим габаритам и относительно маленькому весу, что позволяет их использовать в легковых автомобилях. Кроме этого, топливо постоянно подается с одной и той же мощностью.

- Магистральные ТНВД в автомобиле. Отвечая на вопрос о том, что такое ТНВД в автомобиле, скажем, что таким узлом оснащены все современные автомобили с дизельным мотором. Главное отличие заключается в подаче солярки прямо в рампу, выполняющую роль аккумулирующей емкости. Конструкция насоса обычно состоит из разного количества плунжерных пар. Они начинают двигаться под действием отдельных пружинных элементов, сжатого воздуха или с помощью гидравлики.

Самые распространенные причины поломок ТНВД

Продолжая разговор о том, что такое ТНВД в машине, стоит сказать, что существует множество потенциальных причин его выхода из строя. Однако самой главной причиной неполадок топливного насоса называют использование топлива плохого качества. Впрочем, это касается не только дизельных двигателей, но и бензиновых. Во всей конструкции узла самыми уязвимыми являются плунжерные пары. Обнаруженные на них малейшие потертости говорят о некорректной работе всего ТНВД.

Если разбираться в том, что такое ТНВД на дизеле и поломках данного элемента, важно сказать, что точно определить причину неисправности можно только в сервисном центре, на стенде. Самостоятельно определить то, что с насосом проблемы, можно по таким признакам:

- увеличившийся расход топлива;

- неисправности мотора даже при низких оборотах;

- невозможность завести машину с первого раза;

- перегрев узла и двигателя, соответственно;

- обнаружение протечки дизеля;

- снижение мощности мотора;

- черные выхлопные газы;

- постукивание или любые другие посторонние звуки в моторе.

Если делать вывод о том, что такое ТНВД в авто, стоит сказать, что он является незаменимым агрегатом, аналогов которого до сих пор не было придумано. За все годы существования производители в его конструкции практически ничего не поменяли, а только усовершенствовали отдельные части. Вопрос о том, для чего нужен ТНВД в автомобиле, можно сопоставить с вопросом о том, для чего человеку нужно сердце. Обобщая, можно ответить, что это узел, который обеспечивает бесперебойную циркуляцию топлива по топливной системе, регулирует количество подаваемого топлива в зависимости от нагрузки, нагнетает дизель в форсунки, определят точный момент впрыска топлива в цилиндр.

ОТВЕТИТЬ